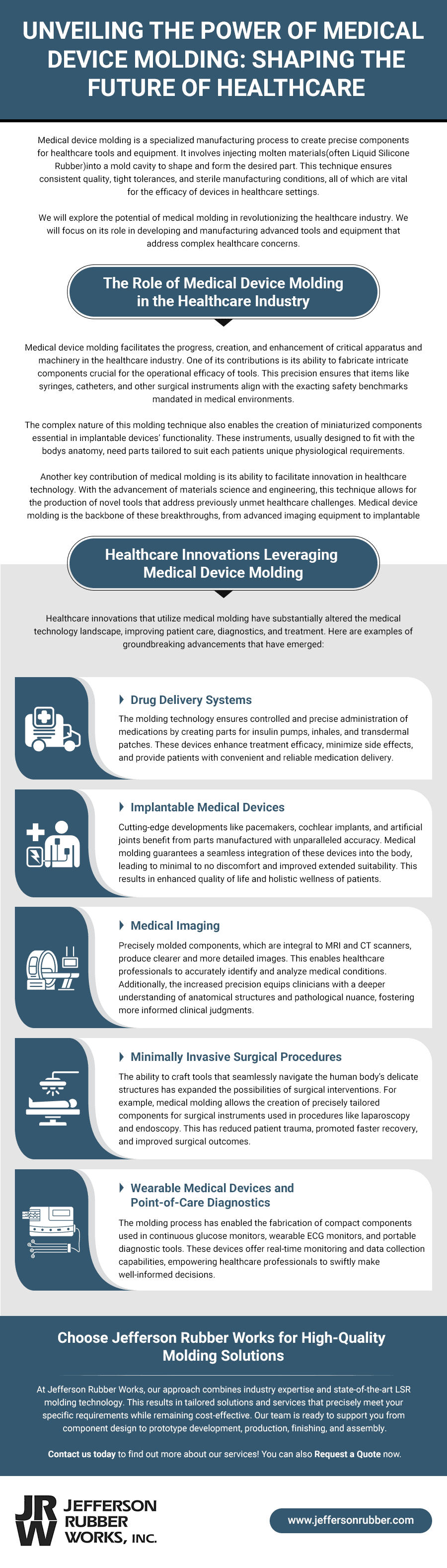

Unveiling the Power of Medical Device Molding: Shaping the Future of Healthcare

Medical device molding is a specialized manufacturing process to create precise components for healthcare tools and equipment. It involves injecting molten materials(often Liquid Silicone Rubber)into a mold cavity to shape and form the desired part. This technique ensures consistent quality, tight tolerances, and sterile manufacturing conditions, all of which are vital for the efficacy of devices in healthcare settings.

In this article, we will explore the potential of medical molding in revolutionizing the healthcare industry. We will focus on its role in developing and manufacturing advanced tools and equipment that address complex healthcare concerns.

The Role of Medical Device Molding in the Healthcare Industry

Medical device molding facilitates the progress, creation, and enhancement of critical apparatus and machinery in the healthcare industry. One of its contributions is its ability to fabricate intricate components crucial for the operational efficacy of tools. This precision ensures that items like syringes, catheters, and other surgical instruments align with the exacting safety benchmarks mandated in medical environments.

The complex nature of this molding technique also enables the creation of miniaturized components essential in implantable devices’ functionality. These instruments, usually designed to fit with the bodys anatomy, need parts tailored to suit each patients unique physiological requirements.

Another key contribution of medical molding is its ability to facilitate innovation in healthcare technology. With the advancement of materials science and engineering, this technique allows for the production of novel tools that address previously unmet healthcare challenges. Medical device molding is the backbone of these breakthroughs, from advanced imaging equipment to implantable sensors.

Healthcare Innovations Leveraging Medical Device Molding

Healthcare innovations that utilize medical molding have substantially altered the medical technology landscape, improving patient care, diagnostics, and treatment. Here are examples of groundbreaking advancements that have emerged:

Drug Delivery Systems

The molding technology ensures controlled and precise administration of medications by creating parts for insulin pumps, inhales, and transdermal patches. These devices enhance treatment efficacy, minimize side effects, and provide patients with convenient and reliable medication delivery.

Implantable Medical Devices

Cutting-edge developments like pacemakers, cochlear implants, and artificial joints benefit from parts manufactured with unparalleled accuracy. Medical molding guarantees a seamless integration of these devices into the body, leading to minimal to no discomfort and improved extended suitability. This results in enhanced quality of life and holistic wellness of patients.

Medical Imaging

Precisely molded components, which are integral to MRI and CT scanners, produce clearer and more detailed images. This enables healthcare professionals to accurately identify and analyze medical conditions. Additionally, the increased precision equips clinicians with a deeper understanding of anatomical structures and pathological nuance, fostering more informed clinical judgments.

Minimally Invasive Surgical Procedures

The ability to craft tools that seamlessly navigate the human body’s delicate structures has expanded the possibilities of surgical interventions. For example, medical molding allows the creation of precisely tailored components for surgical instruments used in procedures like laparoscopy and endoscopy. This has reduced patient trauma, promoted faster recovery, and improved surgical outcomes.

Wearable Medical Devices and Point-of-Care Diagnostics

The molding process has enabled the fabrication of compact components used in continuous glucose monitors, wearable ECG monitors, and portable diagnostic tools. These devices offer real-time monitoring and data collection capabilities, empowering healthcare professionals to swiftly make well-informed decisions.

Choose Jefferson Rubber Works for High-Quality Molding Solutions

At Jefferson Rubber Works, our approach combines industry expertise and state-of-the-art LSR molding technology. This results in tailored solutions and services that precisely meet your specific requirements while remaining cost-effective. Our team is ready to support you from component design to prototype development, production, finishing, and assembly.

Contact us today to find out more about our services! You can also request a quote now.