Medical Silicone Injection Molding

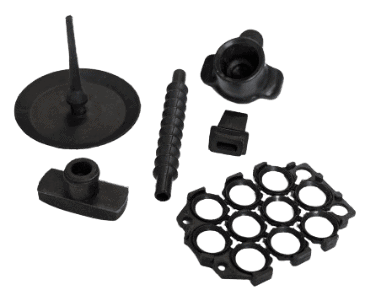

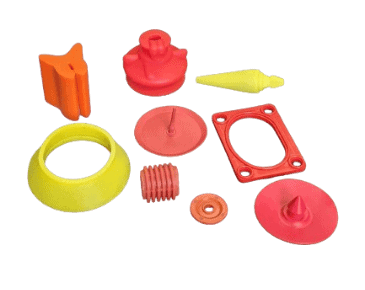

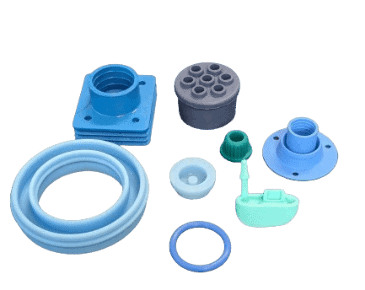

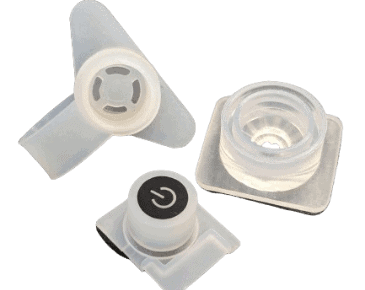

Silicone rubber is frequently used to manufacture high-quality healthcare, industrial, and consumer products. Medical-grade silicone rubber is a specialized material that meets strict medical standards for safety and is used to create flexible, durable medical components.

At Jefferson Rubber Works, Inc., we offer premier medical silicone injection molding services for the medical industry, using fully traceable medical-grade silicone in our products. Our liquid silicone rubber (LSR) injection molded parts and processes adhere to strict ISO standards.

Learn more about our LSR injection molding process, the types of parts we produce, our silicone materials, and more.

Our Process

An ISO 13485:2016 certified manufacturer, Jefferson Rubber Works, Inc. operates a controlled environment Class 8 injection molding cleanroom. Our Medical Products Group provides contaminant-free, flash-less LSR and elastomeric components for various healthcare applications.

We utilize state-of-the-art injection molding equipment that allows us to produce at much higher rates than compression molding processes and with a superior degree of accuracy. Our modern facilities can manage small- to large-volume production runs, prototyping, design consultations, secondary finishing, and assembly.

Benefits of Liquid Silicone Rubber Injection Molding

Medical silicone injection molding processes from Jefferson Rubber Works, Inc. provide the following advantages:

Diverse Applications

Design Flexibility

Biocompatibility

Automation

Extended Product Life

Multi-Material Molding

Jefferson Rubber Works: Quality Liquid Silicone Rubber Injection Molding Since 1975

Jefferson Rubber Works, Inc., has extensive experience in medical silicone injection molding for medical devices, and we are committed to meeting the specific requirements of our clients at all phases of the manufacturing process. As a one-stop shop for all your injection molding needs, we produce high-quality components with fast turnarounds for your mission-critical applications.

Request a quote today to get started on your LSR injection molding project.