The Art of Medical Molding: Revolutionizing Healthcare With Precision

Medical molding (or medical device molding) is a manufacturing process used to create precise plastic or silicone components for healthcare applications. In this method, molten material is injected into a mold, which is cooled and solidified to produce medical parts and tools. Its precision and consistency ensure that the products meet the stringent specifications and quality standards for safe and effective patient care.

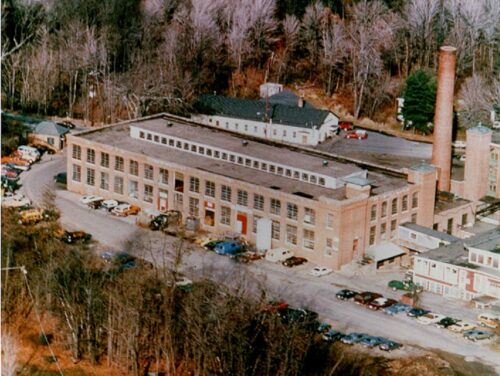

At Jefferson Rubber Works, we integrate industry knowledge with cutting-edge molding technology! This approach delivers highly customized solutions and services that align with our client’s unique needs, all while maintaining cost-effectiveness. Our team is also ready to support our customers from component design to prototype development, production, finishing, and assembly.

The Medical Molding Process

Here is a detailed breakdown of each step in the medical device molding process:

-

1. Material Selection

Medical-grade plastics — such as polycarbonate, polyethylene, or silicone — are often selected for their biocompatibility. They are thoroughly tested and certified to ensure they will not cause adverse reactions when used in contact with the human body. Additionally, they possess specific qualities like resistance to sterilization methods and stability over various temperatures, making them ideal for medical applications.

-

2. Mold Design and Tooling

Precision in mold design is critical as it must align with the specifications of the medical component to be manufactured. This is often achieved using computer-aided design (CAD) software, which can create highly accurate 3D models of the parts. The molds are constructed from robust materials — such as steel or aluminum — and are shaped through various machining techniques.

-

3. Injection Molding

The selected material (in the form of pellets or granules) is heated in a chamber until it reaches a molten state. It is then injected into the mold under specific temperature and pressure conditions. This stage requires accurate control of parameters like heat, humidity, and speed to ensure the material fills the cavity completely and uniformly.

-

4. Cooling and Solidification

The cooling process is carefully controlled to achieve the desired results and prevent defects, warping, or other imperfections in the molded component. In some cases, especially with liquid silicone rubber (LSR), a curing process may be required. This involves subjecting the mold to specific temperatures and time durations to allow the material to fully solidify.

-

5. Ejection

Once the material has sufficiently cooled and solidified, the molded component is carefully removed from the cavity. Ejecting mechanisms — such as pins, air blasts, or mechanical push rods — are typically used to avoid damage or deformation.

-

6. Quality Control

Stringent quality control measures are implemented at various stages of the process. Visual inspections, measurements using tools like calipers or optical comparators, and multiple tests are performed to ensure each part meets specific standards. Other assessments may include checks for dimensional accuracy, material strength, and surface imperfections.

-

7. Secondary Operations

Some components might require additional operations post-molding. These may comprise assembly, where multiple components are combined to form a finished product, or surface treatments like painting or coating. Another option includes sterilization to ensure that the medical tools and devices meet stringent cleanliness and safety standards for healthcare use.

-

8. Packaging and Distribution

Once the products pass quality checks, they are carefully packaged to preserve their sterility and integrity. Packaging methods vary depending on the item and its intended use. For example, sterile packaging uses materials like Tyvek or medical-grade pouches to maintain cleanliness and ensure that the object is ready for use. Components are then distributed to manufacturers for incorporation into various healthcare devices.

Applications of Medical Device Molding

Medical device molding has a wide range of applications in the healthcare industry. Here is a list of some of its common uses:

- Catheters: These rely on molded components for their biocompatibility and precise dimensions for effective use.

- Dental devices: Orthodontic braces, retainers, and mouthguards use injection molding to manufacture parts that fit comfortably and safely in the oral cavity.

- Diagnostic equipment: Components of blood glucose monitors, pregnancy tests, and urine analyzers are produced using injection molding.

- Drug delivery devices: Insulin pens and inhalers use molded components for accurate and convenient drug delivery.

- Implantable devices: Pacemaker enclosures and cochlear implant components are manufactured using molding techniques to ensure that they are biocompatible and safe for long-term use.

- Laboratory consumables: Injection molding is used to create microplates, pipette tips, and test tube racks for clinical and research settings.

- Respiratory equipment: Medical device molding is essential for making components in inhalers, oxygen masks, and ventilator parts.

- Surgical instruments: Forceps, scalpel handles, and clamps are typically constructed using medical-grade molded components.

- Syringes and needles: These ensure accurate dosage delivery for medications, vaccines, and blood sampling.

The Importance of Biocompatibility and Regulatory Compliance in Medical Molding

Biocompatibility and regulatory compliance ensure the safety and efficacy of medical devices. First, biocompatibility ensures that materials used in medical device molding do not cause harmful responses upon contact with the human body. Given the relationship between medical tools and patients, materials are tested rigorously to prevent adverse reactions, making patient safety the top priority.Regulatory compliance goes hand in hand with biocompatibility. Government agencies and authorities have established standards and guidelines to ensure the quality and safety of medical devices. Adherence to these regulations is non-negotiable. Medical molding processes must adhere to Good Manufacturing Practices (GMP) and Quality Management Systems to meet the criteria.

These two aspects instill trust in the industry. Healthcare professionals and patients rely on medical devices, and adherence to manufacturing principles ensures that they are produced with the highest level of integrity. The consequences of non-compliance can be severe, including legal repercussions, product recalls, and, most importantly, potential harm to patients.

Emerging Molding Trends and Technologies in the Healthcare Industry

The adoption of the following innovations in medical device molding demonstrates a commitment to improved patient outcomes:

3D Printing

3D printing allows for the creation of complex and customized medical components. It offers greater design flexibility and faster prototyping. Moreover, its ability to produce intricate designs layer-by-layer is particularly beneficial for creating

patient-specific implants and prosthetics.

Advanced Material Development

Ongoing advancements in material science have resulted in improved resources for medical device molding. They exhibit enhanced biocompatibility, durability, and specialized properties, catering to specific requirements. For example, bioresorbable polymers in implantable tools gradually degrade in the body, eliminating the need for subsequent surgical removal.

Micro Molding for Miniaturization

The demand for smaller, more intricate medical devices has led to the emergence of micro molding. This specialized process enables the production of components with micron-level precision. It is particularly useful for microfluidics, minimally invasive surgical instruments, and implantable medical devices.

Real-Time Quality Control and Inspection Techniques

Rapid advancements in inspection and quality control techniques allow for more stringent quality checks throughout the molding process. These include high-resolution imaging, non-destructive testing, and real-time monitoring systems. They ensure the production of flawless medical components, reducing defects and enhancing patient safety.

Sustainable and Eco-Friendly Practices

There is a growing emphasis on sustainable practices in medical device molding. Manufacturers and designers are exploring eco-friendly materials and processes that reduce waste and environmental impact. This includes biodegradable substances, energy-efficient manufacturing methods, and recycling initiatives to minimize the ecological footprint of the molding process.