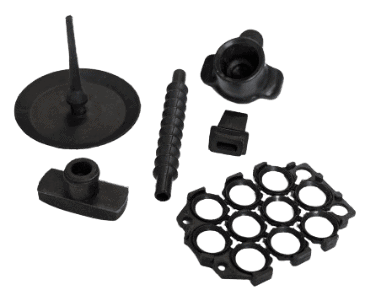

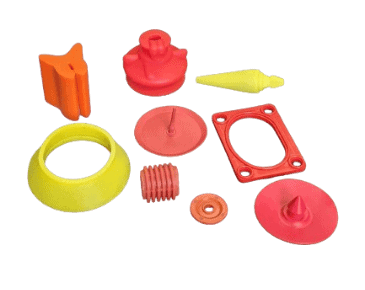

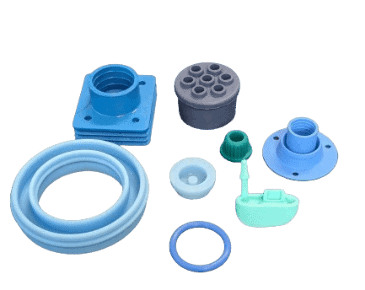

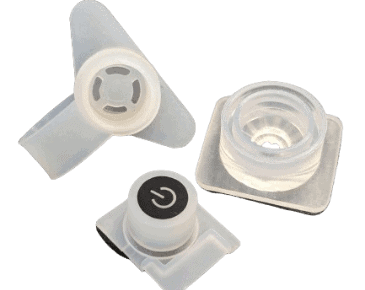

Silicone rubber is frequently used to manufacture high-quality healthcare, industrial, and consumer products. Medical-grade silicone rubber is a specialized material that meets strict medical standards for safety and is used to create flexible, durable medical components.

At Jefferson Rubber Works, Inc., we offer premier medical silicone injection molding services for the medical industry, using fully traceable medical-grade silicone in our products. Our liquid silicone rubber (LSR) injection molded parts and processes adhere to strict ISO standards.

Learn more about our LSR injection molding process, the types of parts we produce, our silicone materials, and more.